Finding Force on Rotating Equipment with a Load Cell

Using a load cell to measure force on rotating equipment might seem tricky, but it's a very effective method. This approach is widely used in industrial applications to monitor things like tension, torque, and material stress. Here's a breakdown of how it works and what makes it so useful.

The Challenge of Measuring Force

Directly measuring force on a moving or rotating object is difficult because the sensor itself needs to rotate with the object or be in a stationary position while the object moves against it. Traditional methods often involve complex setups, but a load cell offers a more streamlined solution.

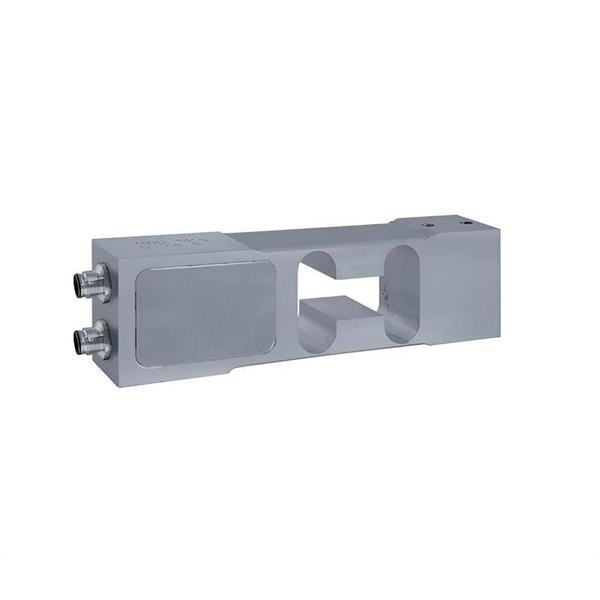

A load cell is a transducer that converts a force into an electrical signal. This signal is usually a tiny voltage change that's proportional to the applied force. The core component of most load cells is a strain gauge, which is a resistive sensor whose resistance changes when it's stretched or compressed.

How to Use a Load Cell on Rotating Equipment

There are two primary ways to use a load cell to measure force on rotating equipment:

Stationary Mounting: This is the most common approach. Instead of attaching the load cell directly to the rotating part, you mount it to a stationary component that's experiencing the force from the rotating equipment.

Example: Measuring Belt Tension. Imagine a conveyor belt system. You can mount a load cell on the stationary frame that holds a pulley. As the belt rotates and creates tension, it pulls on the pulley, which in turn applies a force on the load cell. The load cell then measures this force, giving you a direct reading of the belt's tension.

Mounting on a Pivoting Arm: For some applications, you can mount the load cell on a pivoting arm or lever connected to the rotating part. As the rotating component exerts a force, it causes the lever to pivot, and the load cell measures this pivoting force.

Example: Measuring Torque on a Shaft. A classic method for this is a reaction torque sensor setup. The rotating shaft is connected to a stationary component (like a motor or gearbox) through a torque arm. A load cell is placed at the end of this arm. As the shaft rotates and exerts torque, it creates a reactive force on the arm, which the load cell measures. This measured force can be used to calculate the torque (

τ

) using the formula:

τ=F×r

where F is the force measured by the load cell and r is the length of the torque arm.

Key Components for a Successful Setup

Besides the load cell itself, a complete system for measuring force on rotating equipment typically includes:

Amplifier: The signal from a load cell is very small and needs to be amplified before it can be processed.

Data Acquisition System (DAQ): This system collects the amplified signal from the load cell and converts it into a digital format.

Slip Ring or Telemetry System: For applications where the load cell itself is rotating, you'll need a way to transmit the electrical signal from the rotating part to the stationary data acquisition system. A slip ring is a common choice, but a wireless telemetry system is often preferred for high-speed applications to avoid friction and wear.

Applications and Benefits

Using load cells for this purpose is beneficial in many industries:

Manufacturing: Monitoring tension on winding machines, ensuring consistent torque on assembly lines.

Robotics: Measuring force feedback at joints to improve control and safety.

Aerospace: Testing stress and strain on rotating parts of engines and turbines.

Material Handling: Ensuring proper tension on conveyor systems to prevent slippage and material damage.

The biggest advantage is the real-time data it provides. By continuously monitoring force, you can detect anomalies, prevent equipment failure, and optimize performance. It provides a reliable and cost-effective way to get accurate force measurements in dynamic, rotating environments.

We are also supply in Andhra Pradesh, Arunachal Pradesh, Assam, Bihar, Chhattisgarh, Goa, Gujarat, Haryana, Himachal Pradesh, Jharkhand, Karnataka, Kerala, Madhya Pradesh, Maharashtra, Manipur, Meghalaya, Mizoram, Nagaland, Odisha, Punjab, Rajasthan, Sikkim, Tamil Nadu, Telangana, Tripura, Uttar Pradesh, Uttarakhand, and West Bengal

Keywords

Real-time force monitoring in manufacturing

Strain gauge load cell for material stress

Wireless telemetry systems for rotating sensors

Data acquisition system for load cell signals

Force sensor for conveyor belt tension

Torque sensor setup for rotating machinery

Force measurement in industrial applications

Load cell mounted on stationary component

Measuring torque with load cell on shaft

Load cell force measurement on rotating equipment