Understanding the Tension Transducer 💡

A tension transducer is a vital sensor used to precisely measure the tensile force, or 'pulling' force, applied to a material. These devices are crucial in a wide range of industries, including textile manufacturing, wire and cable production, and papermaking. By converting mechanical tension into an electrical signal, they allow for real-time monitoring and control of processes. This ensures product quality and prevents material damage. The core of a tension transducer often consists of strain gauges that deform under tension, changing their electrical resistance. This change is then amplified and converted into a measurable output. For anyone working with continuous web or wire applications, understanding the role of a tension transducer is key to operational efficiency and safety.

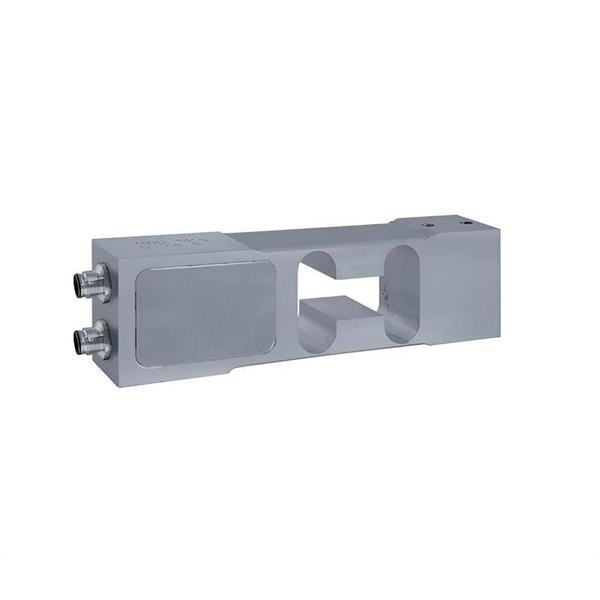

The Working Principle of a Tension Transducer ⚙️

At its core, a tension transducer operates on the principle of converting mechanical force into an electrical signal. When tension is applied to the sensor, its internal structure—typically a carefully machined metal body—deforms slightly. This deformation is measured by strain gauges bonded to the body. Strain gauges are resistors whose electrical resistance changes in direct proportion to the strain they experience. This change in resistance is then measured using a Wheatstone bridge circuit. The output from this circuit is a small voltage change that is directly proportional to the applied tension. This signal is then amplified and processed, providing a clear and accurate measurement of the tension. This robust technology makes the tension transducer indispensable for many industrial applications.

Key Applications of a Tension Transducer 🏭

A tension transducer plays a critical role in numerous industrial applications where precise force measurement is non-negotiable. In the textile industry, they ensure uniform tension on yarns during weaving and spinning. In the paper and plastic film industries, they prevent tearing and wrinkling by maintaining constant web tension on production lines. For wire and cable manufacturers, a tension transducer guarantees consistent product quality and diameter. These devices are also essential in crane and hoist systems for monitoring load and preventing overloads. The versatility of the tension transducer makes it a cornerstone of modern automation and quality control, ensuring smooth and efficient operations across diverse manufacturing sectors.

Choosing the Right Tension Transducer 🛒

Selecting the right tension transducer for your application requires careful consideration of several factors. First, you need to determine the required measurement range—the minimum and maximum tension the device will need to handle. The operating environment is also crucial; factors like temperature, humidity, and potential exposure to chemicals or dust will influence your choice. The type of mounting and the required output signal (e.g., analog, digital) are also important specifications. It’s wise to consult with a reputable tension transducer manufacturer to ensure you choose a device that is accurate, durable, and compatible with your existing control systems. The right choice will save you time and money by preventing costly downtime and production errors.

Benefits of Using a Tension Transducer 📈

Integrating a tension transducer into your manufacturing process offers significant advantages. Primarily, it provides real-time, accurate data on tension, which is essential for maintaining product quality. By preventing excessive tension, you can avoid material breakage, tearing, or stretching, reducing waste and increasing yield.

In many cases, the use of a tension transducer can also lead to increased production speeds, as the system can be automatically controlled to operate at optimal tension levels. Furthermore, these sensors contribute to a safer working environment by preventing equipment overload. Ultimately, the investment in a high-quality tension transducer translates into improved efficiency, reduced costs, and a superior end product.

The Role of Tension Transducers in Robotics 🤖

Robotics is an increasingly important field where the tension transducer is finding new applications. In delicate robotic manipulation, a tension transducer is used to provide feedback on the force applied by a robot’s end-effector. This is particularly useful in tasks like assembly, where a specific amount of force is needed to connect two parts without causing damage. In robotic grippers, they can measure the grip force, ensuring a secure hold without crushing the object. This precise force control is fundamental for creating more dexterous and intelligent robots capable of handling a wider variety of tasks. As robotics technology advances, the demand for sophisticated and reliable tension transducers will continue to grow.

Maintenance Tips for Your Tension Transducer 🛠️

Proper maintenance is essential to ensure the longevity and accuracy of your tension transducer. Regularly inspect the sensor and its mounting for any signs of physical damage, corrosion, or wear. Ensure that all electrical connections are secure and free from moisture or debris. Calibration is another critical aspect of maintenance. Over time, all sensors can experience a slight drift in their measurements, so it’s important to have your tension transducer calibrated periodically according to the manufacturer’s recommendations. By following these simple maintenance steps, you can prolong the life of your device, maintain the integrity of your measurements, and avoid unexpected downtime in your production line.

Tension Transducers in Load Monitoring 🏗️

While often associated with web and wire tension, a tension transducer is also widely used in load monitoring applications. For instance, in crane and hoist systems, they are installed to measure the weight of the load being lifted. This is a critical safety feature that helps prevent overloading, which could lead to catastrophic equipment failure. In mooring lines for ships or anchor systems for offshore platforms, a tension transducer can continuously monitor the force on the lines, providing valuable data to ensure stability and safety, especially during adverse weather conditions. The ability to accurately measure pulling force makes the tension transducer an indispensable tool for ensuring safety in many heavy-duty lifting and structural applications.

The Future of Tension Transducer Technology 🚀

The field of tension transducer technology is continuously evolving. One key trend is the development of smarter sensors with integrated electronics. These 'smart' transducers can perform self-diagnostics and communicate directly with control systems, reducing the need for external signal conditioners. Wireless technology is also becoming more common, allowing for easier installation and greater flexibility in hard-to-reach locations. Miniaturization is another important trend, leading to smaller, more compact sensors that can be integrated into new applications where space is at a premium. These advancements will make tension measurement even more accessible, accurate, and essential for the next generation of automated manufacturing and control systems.

The Importance of Accuracy in a Tension Transducer 🎯

The accuracy of a tension transducer is paramount to its effectiveness. A small error in tension measurement can lead to significant problems, such as material tearing, wrinkling, or an inconsistent final product. The precision of the sensor depends on its design, the quality of its components, and proper calibration. High-quality tension transducer devices are designed to minimize hysteresis and non-linearity, ensuring that the output signal is a true representation of the applied tension. Investing in a high-accuracy tension transducer is a critical step towards achieving consistent product quality, reducing waste, and maintaining a competitive edge in your industry.

Keywords

Wireless tension transducer technology advancements

High-accuracy tension measurement devices

Tension transducer for papermaking industry

Integrated electronic smart tension sensors

Real-time force measurement in robotics

Tension transducer calibration and maintenance tips

Wire and cable tension sensing technologies

Load monitoring for crane and hoist systems

Web tension monitoring in manufacturing processes

Precision tension transducer for industrial applications