1. Why a Web Tension Load Cell is Essential for Quality Control

In manufacturing, precision is everything. A web tension load cell plays a critical role in ensuring that a continuous web of material—be it paper, film, or metal—is handled with the perfect amount of tension. Without a reliable web tension system, you risk costly issues like material breaks, wrinkles, or uneven printing. This not only wastes materials but also leads to product defects and customer dissatisfaction. A load cell provides a closed-loop feedback signal, allowing your control system to make real-time adjustments and maintain the correct web tension. This precise control is the foundation of consistent quality and high-speed production. The right web tension system can significantly improve your process efficiency and product output.

2. Choosing the Right Web Tension Load Cell: A Buyer's Guide

Selecting a web tension load cell is a crucial decision that can impact your entire production line. To make the right choice, you need to consider several factors. What is the maximum and minimum tension you need to measure? What is the width and weight of your material? The physical design of the load cell is also important, with options like dead shaft, live shaft, and pillow block mounts. You must also consider the operating environment, including temperature and potential for contaminants. A reliable load cell is a long-term investment that ensures your machine can handle variations in the material and maintain consistent web tension. This precision is what separates a good process from a great one, allowing for optimal web tension control across a wide range of applications.

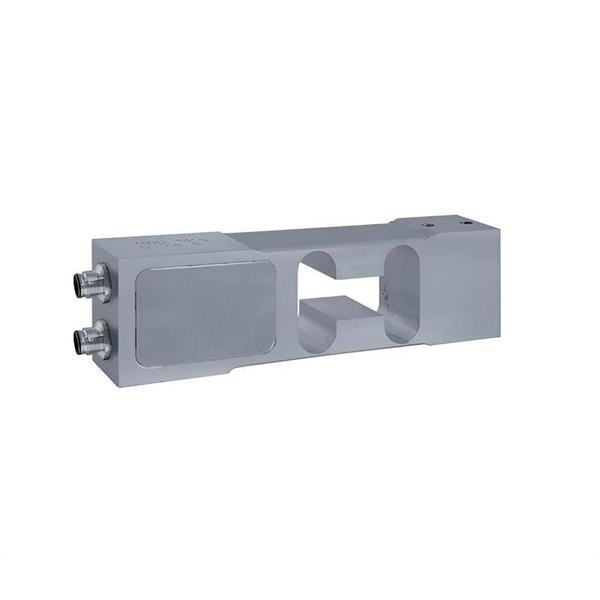

3. The Science Behind a Web Tension Load Cell

A web tension load cell is a precise instrument that measures the force exerted on a web of material. At its core, the device uses strain gauge technology. When the web pulls on the roller, the load cell's internal flexural element deforms ever so slightly. This deformation is measured by sensitive strain gauges, which convert the mechanical force into a proportional electrical signal. This signal is then sent to a controller, which interprets the data and adjusts motors or brakes to maintain the desired web tension. Understanding this process is key to appreciating the importance of a properly calibrated load cell. This continuous feedback loop ensures that the web tension remains within a tight tolerance, preventing costly production errors and improving overall line performance.

4. Troubleshooting Common Issues with Your Web Tension Load Cell

Even the best equipment needs occasional maintenance. If you're experiencing problems with your tension control, start by checking your web tension load cell. Common issues include improper calibration, which can lead to inaccurate readings, or mechanical misalignment, which can skew the force measurement. Electrical interference from other machinery can also affect the load cell's signal. It's important to consult the manufacturer's guide to ensure your device is properly installed and maintained. A systematic approach to troubleshooting can quickly identify the root cause of the problem, allowing you to restore accurate web tension control and prevent costly downtime. Maintaining your system ensures optimal web tension for every product run.

5. Integrating a Web Tension Load Cell into Your Existing System

Upgrading your web handling system with a new web tension load cell can be a simple and effective way to improve performance. Most modern load cells are designed for easy integration with existing PLCs and control systems. The key is to ensure proper wiring and to perform a careful calibration. The load cell's output signal—typically a voltage or current signal—can be wired directly to your controller's analog input. Proper calibration is a crucial step that involves setting the zero and span points of the load cell to match your specific application. By following these steps, you can seamlessly add a new load cell, gaining the benefits of improved web tension and a more stable production process. This upgrade can lead to a new level of control over your web tension.

6. The Benefits of Upgrading to a Digital Web Tension Load Cell

While analog load cells have been the industry standard for decades, digital web tension load cells are becoming increasingly popular. These devices offer several advantages, including built-in signal processing, which can eliminate the need for external amplifiers and reduce electrical noise. Digital load cells often feature advanced diagnostics and communication protocols, simplifying installation and troubleshooting. They offer superior accuracy and stability, which is especially important in high-speed or sensitive applications. An upgrade to a digital load cell can lead to tighter web tension control, more reliable data, and greater insight into your process. This improved control over web tension can significantly enhance product quality and reduce waste.

7. Maximizing Production Efficiency with a High-Performance Web Tension Load Cell

In a competitive market, maximizing efficiency is paramount. A high-performance web tension load cell is a key component in achieving this goal. By providing accurate, real-time data, it allows your control system to prevent issues before they occur. This means fewer material breaks, less waste, and reduced downtime. A precision load cell can handle the demands of high-speed lines and sensitive materials, ensuring consistent product quality at every stage of the process. Investing in a quality load cell is a direct investment in your company's profitability. The right web tension system ensures that every product is made with the right amount of web tension, leading to a higher-quality output and a better bottom line.

8. Web Tension Load Cell vs. Dancer Roll Systems

When it comes to tension control, a web tension load cell is often compared to a dancer roll system. While both methods serve a similar purpose, their approaches are fundamentally different. A dancer roll uses a movable roller to physically absorb changes in tension, but its reaction time can be slow and it is less precise. In contrast, a load cell provides a direct, electronic measurement of the actual force on the web. This closed-loop feedback allows for immediate and highly accurate adjustments, making it the superior choice for applications where precision is critical. For consistent, reliable web tension, a load cell is the most effective solution, providing a level of control that a dancer roll system simply cannot match. This level of web tension stability is key for modern manufacturing.

9. The Future of Web Tension Load Cell Technology

The field of web handling is constantly evolving, and so is the web tension load cell. We are seeing the rise of smart sensors and the integration of IoT technology. These smart load cells not only measure tension but also provide diagnostic information and predictive maintenance data. They can communicate wirelessly with other devices, simplifying installation and improving overall system visibility. As manufacturing moves towards greater automation and data-driven processes, the load cell will become an even more intelligent and integrated component. The future of web tension technology is one of connectivity and intelligence, providing manufacturers with unprecedented control and insight into their web tension processes.

10. The Unseen Importance of a Web Tension Load Cell

You might not see it, but a web tension load cell is a crucial component in the production of countless everyday items. From the plastic film on your food packaging to the paper in your newspaper, a load cell ensures that the material is handled correctly. Without precise tension control, labels would be crooked, packaging would be flawed, and printing would be misaligned. The tireless work of a load cell behind the scenes ensures that these products are made efficiently and with consistent quality. The next time you see a perfectly wrapped product, you can appreciate the intricate dance of a production line, controlled by a highly reliable web tension system. The accuracy of a web tension system is a testament to the technology.

Keywords

IoT-enabled smart web tension load cells

Web tension load cell vs dancer roll system

Benefits of digital web tension sensors

Troubleshooting web tension load cell issues

High-speed web tension load cells

Web tension control system integration

Web tension load cell calibration tips

Digital vs analog web tension load cells

Precise web tension measurement technology

Web tension load cell for manufacturing